Frequently Asked Questions

Last updated: August 21 , 2023

ABOUT BWXT NEC

How many people work for BWXT Nuclear Energy Canada (BWXT NEC)?

BWXT NEC employs nearly 500 people across our three locations in Arnprior, Toronto and Peterborough.

Approximately 400 people work in high-tech, manufacturing and administrative positions at our Peterborough facility. Almost half of these employees are engineers in disciplines such as software development, metallurgy, mechanical engineering, electrical engineering and systems engineering

At our Arnprior and Toronto facilities, we employ about 40 employees at each location. Employees at our Toronto site hold jobs in manufacturing, engineering, environmental health and safety and several other critical fields. Employees in Arnprior hold jobs in manufacturing (Millwright, Electrician, Operator), environmental health and safety, and Quality.

Where can I find information about jobs at BWXT NEC?

Available positions are posted online at bwxt.com/careers.

What do you make in Peterborough?

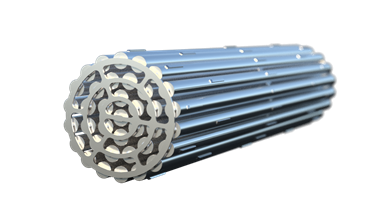

At BWXT NEC in Peterborough, we assemble fuel bundles for use in CANDU® reactors. Natural uranium pellets are produced at our Toronto facility, and zirconium tubes are manufactured at our Arnprior facility. These components are then shipped to our Peterborough operation, where they are assembled into fuel bundles that meet the stringent requirements of reactor operating conditions.

BWXT’s fuel handling, reactor inspection, maintenance tooling and delivery systems are also designed and manufactured in Peterborough. These highly engineered systems and tools support refurbishment requirements for reactor refuelling, fuel channel inspection and maintenance, and other reactor operating needs.

CANDU® fuel bundle

What do you make in Toronto?

At BWXT NEC in Toronto, we make ceramic pellets from natural uranium powder (not yellowcake). Our Toronto facility receives natural uranium oxide powder from Cameco Corporation in Port Hope. After pressing, baking, grinding the powder (to a precise size) and inspection, we send the pellets to our facility in Peterborough. There, they are placed into fuel bundles for CANDU® power stations.

The pellets produced at our Toronto facility go on to provide about 25% of Ontario’s electricity.

Natural uranium ceramic pellet

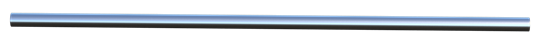

What do you make in Arnprior?

At BWXT NEC in Arnprior, we make zirconium-alloy tubes, which are used in the production of CANDU® fuel bundles. BWXT NEC has been producing tubes for use in CANDU® fuel reactors for over 40 years. We are a qualified supplier to both Canadian and international markets.

Zirconium-alloy tube

URANIUM & EMISSIONS

What is uranium?

Uranium is a naturally occurring, weakly radioactive element that is present at low levels in the environment. This element is found naturally in soil and rocks, in the water we drink and even in the air we breathe.

Because uranium is a naturally occurring, low-level radioactive material that is found across virtually all parts of our environment, it contributes to what is called “natural background radiation.”

The amount of uranium BWXT NEC emits is insignificant when compared to the levels that already exist naturally in the environment. BWXT NEC’s Toronto location emits about 0.003 of the regulatory limit set for air emissions.

Do you use enriched uranium?

No. We are not licensed to use or possess enriched uranium.

Are uranium emissions from your facilities safe for the public?

Yes. The amount of uranium BWXT NEC emits is an insignificant source next to the levels that already exist naturally in the environment. BWXT in Toronto emits about 1% of the regulatory limit set for emissions, and BWXT in Peterborough is a near-zero emissions facility.

The main safety concerns associated with it relate to chemical toxicity at high exposures, according to Health Canada, the US Environmental Protection Agency, the World Health Organization and the United Nations Scientific Committee on Atomic Radiation.

Do the natural uranium pellets used at the Peterborough facility pose a radiation risk to the public?

No. The use of uranium is controlled by a robust program that protects the health and safety of our employees, the public and the environment. Our uranium emissions are carefully controlled using a defence-in-depth approach, and air and water emissions are monitored for the presence of uranium.

The potential for emissions is exceptionally low. We continuously monitor uranium emissions, and results show that our Peterborough operation is a near-zero emissions facility. In 2022, the estimated annual public dose from our Peterborough facility was 0.0115 mSv (milliSieverts).

The Peterborough facility (along with our Toronto operation) is licensed by Canada’s nuclear regulator, the CNSC. BWXT NEC is committed to meeting all its licence requirements.

Do you monitor uranium emissions to air from your facility in Peterborough?

Yes. A single process uranium air emission point exists in the Peterborough facility. Continuous in-stack monitoring is performed by drawing a sample of air across a filter capable of trapping uranium dust. The samples are analyzed by an external independent laboratory. Due to the nature of the process and our stack sample results to date, perimeter monitoring is not required.

Recent stack air monitoring results can be found here.

Do you monitor uranium emissions to water from your facility in Peterborough?

Yes. Waste water is generated from routine cleaning activities in the fuel bundle assembly area. All potentially uranium-contaminated waste water is held in a drum, filtered, and samples are sent to an external independent laboratory for analysis. This waste water is only released to the sanitary sewer once the test results confirm it meets release requirements.

Recent water monitoring results can be found here.

Do you monitor uranium emissions to air from your facility in Toronto?

Yes. Continuous in-stack sampling is conducted for all six stacks at the facility. A sample of air is drawn across a filter capable of trapping uranium dust. The samples are analyzed in-house daily and verified externally by an independent laboratory.

Recent stack air monitoring results can be found here.

In addition to stack air sampling, perimeter sampling is conducted. Perimeter samples are high-volume air samples drawn at five positions strategically located around the facility perimeter. Perimeter samples are analyzed externally by an independent laboratory. In both cases, the external independent laboratory tests the filter papers by delayed neutron activation analysis.

Recent boundary air monitoring results can be found here.

Do you monitor uranium emissions to water from your facility in Toronto?

Yes. Water is used in the production process and to clean protective clothing, floors and other janitorial functions. The water is first held in storage tanks at the facility, treated to remove uranium dioxide, tested and only released in batches once the test results confirm it meets release requirements.

Recent water monitoring results can be found here.

Does natural uranium pellet manufacturing utilize a large amount of water?

Although the current Peterborough manufacturing operation utilizes essentially no water within the uranium operation, pelleting operations in Toronto utilize small amounts of water – approximately 3,800 litres per day. Most of that water is used for laundry and cleaning activities. For context, the average household in Toronto used approximately 765 litres of water per day.

Is natural uranium pellet manufacturing a dusty operation? How does it impact air, water and soil?

Pellet production has been done safely at our existing facility in Toronto for over 50 years. There are well established limits set by both the Canadian Nuclear Safety Commission (CNSC) and the Ministry of Environment, Conservation and Parks (MECP) for emissions.

Most steps in the production of pellets do not generate significant airborne dust. Those that do are serviced by robust ventilation systems that filter particulate from the air using multiple stages of filtration, including High Efficiency Particulate Air (HEPA) filters that filter 99.97% of particles. Therefore, releases to the environment are a small fraction of limits set by CNSC and MECP.

Similarly, water is treated and sampled to be confirmed below any release limits prior to discharge. If it doesn’t meet the criteria, it isn’t released. In Toronto, we conduct annual soil tests both onsite and in the surrounding community to ensure we meet or exceed regulatory environmental standards.

If natural uranium pellet manufacturing were to occur at BWXT NEC Peterborough, how would this change impact your emissions?

Introducing pelleting to Peterborough, if that were to occur, would see emissions similar to, but no higher than our existing pelleting operation in Toronto. In 2022 in Toronto, emissions to air were less than 1% of the Licensed Release Limit and emissions to water are less than 0.3 percent of the Licence Release Limit.

Further, any project to incorporate pelleting into the existing Peterborough operation would make use of the best available technologies to minimize emissions to be as low as reasonably practical.

Have you conducted a risk assessment that takes into account how manufacturing natural uranium pellets in Peterborough would impact the public and environment?

Yes, a consolidated Environmental Risk Assessment (ERA) has been conducted and concluded the following:

- Overall, estimated emissions associated with consolidated operations at the Peterborough facility are determined to be low.

- All radiological and non-radiological emissions are and will continue to be, well below regulatory limits.

- For human health, there are no radiological or non-radiological risks to members of the public.

- For ecological health, there are no radiological or non-radiological risks to the environment or wildlife.

- Potential impacts of future activities at the Peterborough facility, should pelleting occur, are anticipated to be similar to those at the existing Toronto operation. Our Toronto operation does not cause any adverse environmental or human health impacts.

- BWXT NEC has a well-established and mature environmental monitoring program. The same environmental monitoring programs used in Toronto would be applied to our Peterborough operations. These programs are considered effective in protecting human health and the environment.

You can find the consolidated Environmental Risk Assessment (ERA) on our website, here: https://www.bwxt.com/bwxt-nec/safety/licensing

RADIATION

What is radiation?

Radiation is energy in the form of waves or particles. Radiation doesn’t just come from nuclear energy. It’s all around us – and we’re exposed to both natural and man-made sources of radiation daily. There are two types of radiation, ionizing and non-ionizing. Some examples of non-ionizing radiation include microwaves, radio waves and television signals. Ionizing radiation comes from natural sources and man-made sources such as X-ray machines and nuclear power plants.

The Canadian Nuclear Safety Commission (CNSC) regulates the nuclear energy industry to limit the radiation that employees and members of the public receive. Using studies performed by the International Commission on Radiological Protection on acceptable levels of radiation exposure, the CNSC has set limits of 50 mSv (millisievert) per year, or 100 mSv per five-year span for workers. The regulatory limit for members of the public is 1 mSv per year.

BWXT NEC has a comprehensive radiation protection program and is guided by the principles of ALARA (as low as reasonably achievable). We use the best available technology to restrict uranium emissions and ensure emissions from our facilities are as low as possible. The small amount of uranium emissions that do occur does not pose a risk to members of the public.

Learn more about radiation here.

Can you really compare the radiation dose from sources like food, air travel and medical procedures to the radiation dose from natural uranium?

For radiation exposure to people, there are standard methods to account for the different types of radiation and the different organs of the body that are exposed. Equivalent dose (expressed in mSv) is calculated for individual organs (e.g. skin). It is based on the absorbed dose (amount of energy deposited) to an organ, adjusted to account for the type of radiation (i.e. alpha, beta or gamma). Effective dose (expressed in mSv) is calculated for the whole body. It is the addition of equivalent doses to all organs, each adjusted to account for the sensitivity of the organ to radiation.

Is there a safe amount of radiation?

Yes. The Canadian Nuclear Safety Commission (CNSC) and international agencies, including the International Atomic Energy Association (IAEA), have established acceptable levels of radiation exposure from nuclear activities. Everyone has an annual background radiation exposure from naturally existing radiation that surround us every day (including minerals like uranium, cosmic rays from the sun, radioactive potassium, and gases). In Canada, this is about 1.8 mSv. The CNSC limit for incremental dose to members of the public is 1 mSv, which represents a small increase over the normal background radiation in Canada. According to the United Nations Scientific Committee on the Effects of Atomic Radiation (UNSCEAR), significant risks in radiation exposure are unlikely to be observed in doses below 100 to 200 mGy (milligray) which is 100 to 200 mSv for gamma radiation.

BERYLLIUM & EMISSIONS

What is beryllium?

Beryllium is a lightweight but strong metal found in the earth’s crust. Beryllium is a naturally occurring stable element that is present in a variety of materials including rocks, coal and oil. It can also be found commercially in everything from cell phones and airbag sensors to aircrafts and pacemakers. Beryllium is known to be carcinogenic and the primary concern is inhalation. Beryllium can be hazardous if its use is not properly controlled.

What do you use beryllium for? What are the health concerns and how do you control emissions?

Beryllium is used in small amounts to join portions of the fuel bundle together. Beryllium is deposited onto small sheets of zirconium, which are converted to appendages. These appendages are brazed onto tubes that make up our fuel bundles. BWXT NEC utilizes about 20 kilograms of beryllium per year at the Peterborough facility.

At BWXT NEC, the highest risk area is the vapour deposition process, which is contained in its own small room with ventilation. Our beryllium emissions are carefully controlled using a defence-in-depth approach: The beryllium coating area is in a secure part of our facility that is approximately 500 square feet. There is limited access to this area, and only highly trained employees may enter while wearing a respirator. The facility has a specialized ventilation system, and air inside our facility is frequently sampled. The ventilation system contains two stages of filtration, with the final stage being a High Efficiency Particulate Air filter, which is capable of trapping 99.97% of particles. Our filtered exhausts are monitored continuously, and emissions from our facility are exceptionally low. The concentrations in the stack are lower than the Ministry of Environment, Conservation and Parks (MECP) limit at the fence line.

Should I be concerned about beryllium in soil around the facility in Peterborough?

No. The analytical results for uranium and beryllium concentrations for all soil samples analyzed are without exception well below the acceptable standard published by the Ministry of Environment, Conservation and Parks (MECP) Table 1 Background Site Condition Standards. Based on the results of the sampling program there is no evidence that uranium or beryllium used at the BWXT NEC facility has had any impact on Peterborough soils. No risk has been identified to the soils or to the public of Peterborough.

This is confirmed by the Canadian Nuclear Safety Commission (CNSC) through their Independent Environmental Monitoring Program (IEMP). To see CNSC results and learn more about the CNSC IEMP, visit their website here.

Are beryllium emissions from the Peterborough facility safe for the community?

Releases are all within allowable limits and are exceptionally low. In fact, beryllium emissions have been deemed insignificant in accordance with the Ministry of Environment, Conservation and Parks (MECP) methodology because they are several hundreds of times lower than MECP limits. Regardless, monitoring of beryllium is performed to ensure releases remain very low

EMERGENCY PREPAREDNESS

How are you prepared for an emergency?

The safety of our employees, members of the public and the environment is our first priority.

Both our Toronto and Peterborough facilities perform emergency response drills regularly. We also schedule drills with outside emergency services and provide them with training about our facilities. This ensures that any response to an emergency event will be a coordinated one.

In the event there is an emergency, BWXT has a comprehensive emergency response plan for each site which is continually updated and shared with local fire and other public health emergency services. Like all industrial businesses, each BWXT facility has established emergency prevention programs to minimize the risk of fires and other hazardous events, as well as robust response plans that prescribe the actions to be taken to prevent or minimize potential health and environmental hazards.

Our site response plans provide guidelines for emergency staff and plant personnel for using sound emergency management practices to fulfill both CNSC operating license requirements and industry standards for Emergency Planning.

We also undertake annual exercises to ensure that our teams know exactly what to do, to safeguard public health and the environment in the plant and the surrounding community.

What if there is a flood?

In 2004, Peterborough experienced a major rain event, when the city received almost the entire volume of a 24-hour, 100-year storm in only one hour. Even in that very large event there was only minor flooding in our Peterborough building. Since that time, a berm has been constructed around the fuel loading area where pellets are handled. The purpose of the berm is to contain any water originating in the area, and to exclude flood water from entering the area. In addition, the City of Peterborough has implemented recommendations to better manage storm water and flooding events.

What if there is a fire?

BWXT has a comprehensive emergency response plan for each site which is continually updated. Like all industrial businesses, each BWXT facility has established emergency prevention programs to minimize the risk of fires and other hazardous events, as well as robust response plans that prescribe the actions to be taken to prevent or minimize potential health and environmental hazards.

Why isn’t the public consulted with respect to emergency planning?

BWXT contemplates all accident scenarios, including low probability events. There are no requirements for the public during a drill or emergency as there are no credible accident scenarios that require evacuation or sheltering in place due to a release of radiation from either site. Neither site houses a nuclear reactor, but rather natural uranium, which cannot become highly radioactive until it is installed in a nuclear reactor.

For information on any emergency situation, call 1-855-696-9588.

Does BWXT NEC have insurance?

BWXT maintains a diversified portfolio of insurance coverages appropriate for the size and scope of its operations. This coverage includes public liability for offsite damages or injuries. Our insurance information is confidential, as our insurance providers require confidentiality.

HYDROGEN TANK IN TORONTO

Why do you have a hydrogen tank on site?

Hydrogen is used at BWXT NEC’s Toronto facility for pellet sintering. Sintering is a process that turns powder into a solid form. The natural uranium dioxide pellets are sintered in a high-temperature furnace with a hydrogen atmosphere to harden them into a ceramic.

Is the hydrogen storage tank in Toronto safe for area residents?

Yes. The hydrogen storage tank at our Toronto facility is sited, installed, operated and maintained according with all requirements and is inspected in accordance with the requirements of the Technical Standards and Safety Authority of Ontario (TSSA). The tank is a low-pressure liquid hydrogen system, operating at less than 150 psi (compared to gaseous hydrogen cylinders that operate at approximately 2500 psi).

BWXT NEC has reviewed many accident scenarios in conjunction with the hydrogen tank. Through this analysis, we are able to conclude that there are no credible accident scenarios resulting in:

- Structural damage to site buildings with a release of uranium

- Structural damage to offsite buildings

- Injury to persons from a “blast”

In very low likelihood events, broken windows in the immediate area could occur. Although exceptionally unlikely, a hydrogen fire could expose individuals outdoors and in the immediate vicinity to heat, which would cause them to increase distance or move indoors to limit potential injury.

The hydrogen is stored cryogenically as a liquid located near the centre of the property as far away from neighbouring structures as possible. The tank at our facility is smaller than the tanks seen transporting hydrogen by road on a regular basis which can be 12,000 gallons or even larger.