BWX Technologies, Inc.'s (BWXT) Fatigue and Fracture Laboratory (F&FL) routinely performs a wide variety of mechanical test methods on metallic samples. The F&FL is staffed by experienced engineers and technicians and is directly supported by the Hot Machine Shop to ensure accurate and reproducible test results. Standard or non-standard specimens are designed by engineers, machined, and then tested in the F&FL.

Experience

The F&FL has handled more than 40 Reactor Vessel Surveillance Program (RVSP) capsules. RVSP capsules are usually irradiated in reactors for varying lengths of time and then withdrawn from the reactors for testing. The F&FL has also been instrumental in several projects where highly irradiated components, such as vessel internals, were removed from a reactor for mechanical testing.

Equipment

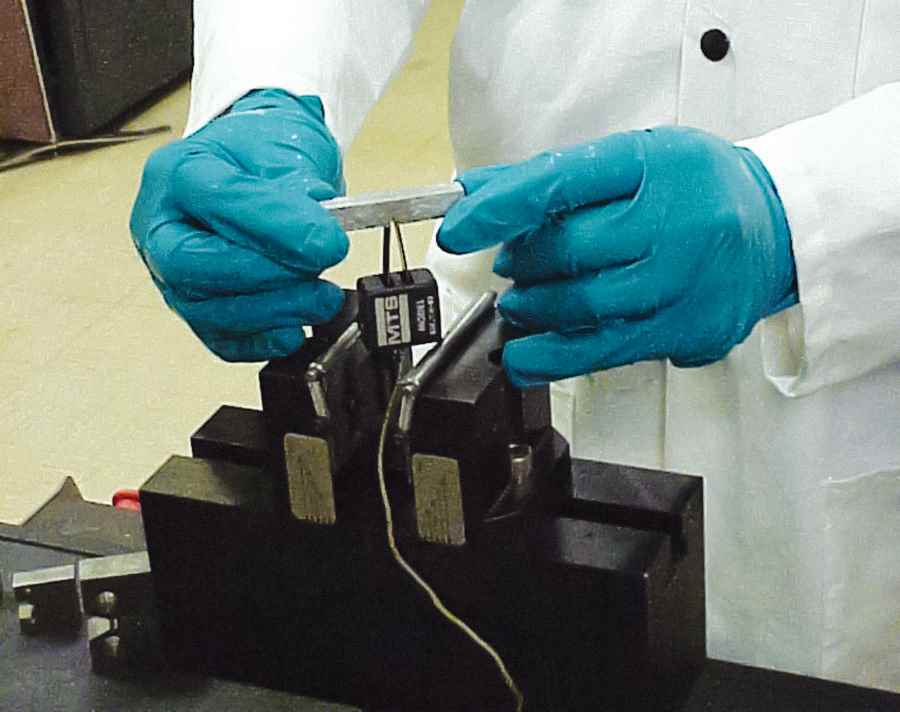

The F&FL's equipment includes two MTS 220 kN servohydraulic test machines and a Satec 240 ft-lb Charpy impact tester. These machines are surrounded by 2-4 inches of lead to provide shielding for operators. Charpy impact, tension and compact tension fracture toughness tests are regularly performed in this laboratory, in accordance with the appropriate ASTM standards. Remote handling tools and automatic specimen loading devices are available for transferring and loading specimens. The F&FL is designed to handle specimens out-of-cell with radiation levels as follows (beta + gamma, single specimen):

- Charpy specimen - 2000 mrem/hr at 30cm

- Tension specimen - 2000 mrem/hr at 30cm

- Compact tension specimen - 7000 mrem/hr at 30 cm

However, specimens with higher radiation levels can be handled if additional shielding is erected around the MTS test machine or the Charpy tester. An example of a project requiring this setup involved highly-irradiated bend test specimens. These specimens had been irradiated to high fluences in a test reactor at high fluxes and had radiation levels up to 30 R/hr at 30 cm. The testing of these specimens was successfully completed in the F&FL with satisfactory results. Mechanical tests are performed in accordance with the appropriate ASTM standards.

Services

- Charpy impact testing (ASTM E23 and A370)

- Tension testing (ASTM E8 and E21)

- Fracture toughness testing (ASTM E1820)

- Low-cycle fatigue testing (ASTM E606)

- High-cycle fatigue testing (ASTM E466)

- Fatigue crack growth rate testing (ASTM E647)

- Transition region fracture toughness testing (ASTM E1921)

- Vickers and Knoop microhardness testing

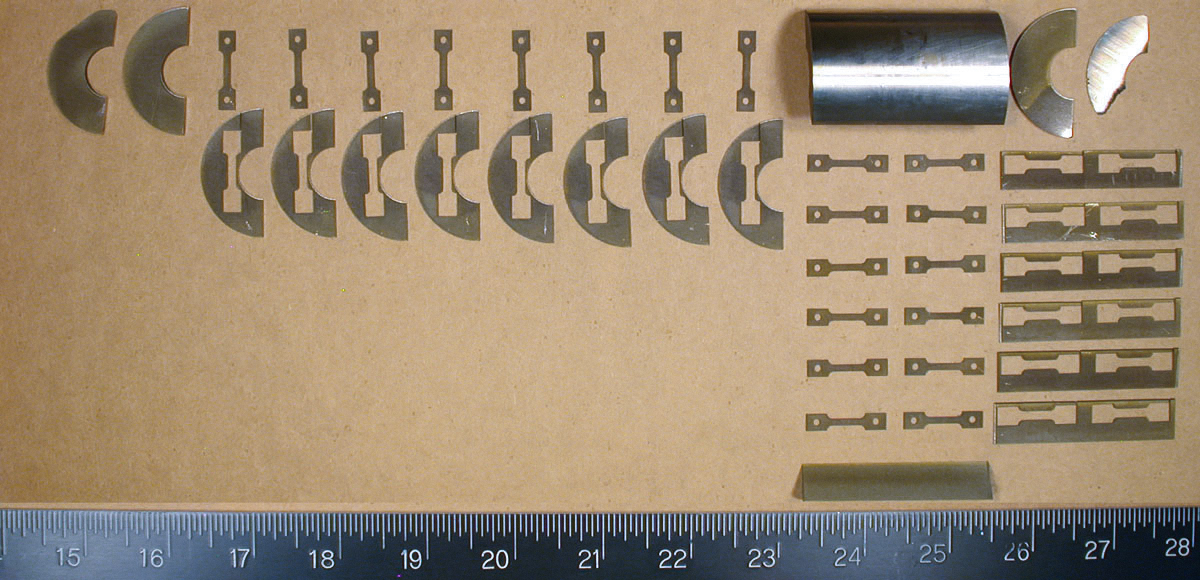

- Miniature specimen machining and testing