Home » Sectors » Nuclear Energy » Field & Engineering Services » Fuel Handling

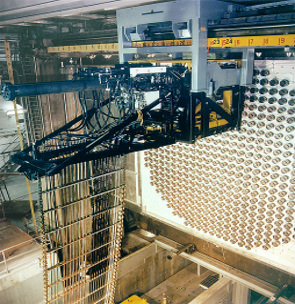

As a global leader in the design, manufacture, testing, and service of specialized equipment for on-power refueling, reactor maintenance, and nuclear medicine delivery, BWXT’s Fuel Handling & Engineered Solutions (FHES) team is at the forefront of solving some of the nuclear industry’s most complex challenges. We are the original designer of the automated CANDU refueling systems, enabling 24/7 on-power refueling and supporting carbon-free energy generation in nuclear plants across Canada.

Our innovations extend beyond power generation. BWXT is also the designer of the Target Delivery System at Ontario Power Generation’s (OPG) Darlington Nuclear Generating Station. This innovation is one of the largest medical isotope irradiation systems in the world and plays a vital role in the production of life saving medical isotopes.

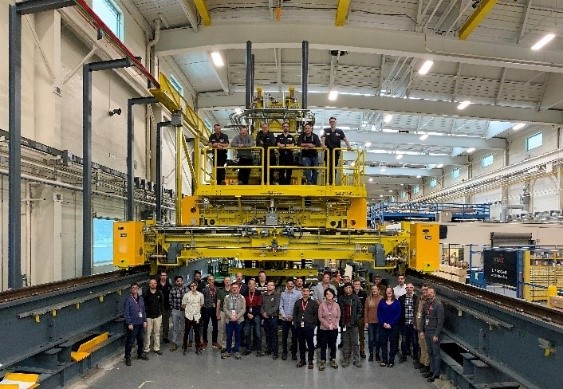

Our services include design, manufacture, installation, commissioning, and spare parts supply. In addition to meeting our customers’ equipment needs, our team of experts provide both timely and responsive on-site engineering support for our installed base with 67,000 square feet of manufacturing space, our Peterborough facility is able to design, procure, manufacture, assemble and test all in one location.

We have over 350 experienced and adaptable employees in Peterborough who partner with our customers to meet their needs. With over 150 engineers and 50 technicians, we strive for excellence and continuously improve our technology, ensuring that our products are up to date with the latest advancements while meeting the highest quality standards.

We provide customers with an in-depth knowledge base through our detailed and up-to-date maintenance manuals and comprehensive technical training. We also offer maintenance and engineering services with experienced engineers who are ready to respond when needed.

As part of Ontario’s long-term energy plan, the four reactors at the OPG’s Darlington Nuclear Generating Station are being refurbished to double their original operating life. As part of this life-extension effort, BWXT worked with OPG to ensure the Fuel Handling system was set to operate for another 30 years.

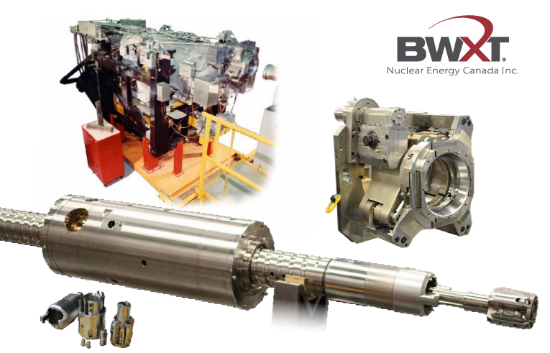

A key part of this plan is the ability to overhaul the eight Darlington Fueling Machine heads without interrupting the continuous fueling of the reactors. Leveraging our experience in supplying Maintenance Kits, BWXT proposed a strategy of supplying overhaul kits for each of the eight Darlington Fueling Machine heads to facilitate a rolling refurbishment of each head coinciding with scheduled maintenance. In addition to like-for-like replacement, BWXT took the opportunity to incorporate numerous design upgrades to the various systems to improve operating performance, reliability and longevity going forward.

The unique kit structure includes 650 discrete components, nine large assemblies comprising over 1000 sub-components, plus numerous critical spares. The assemblies include all the most complex operating mechanisms of the Fueling Machine including Homing and Locking, Charge Tube and Ram, Input Drives and Gearbox which were built at BWXT and fully tested in their assembled condition. This strategy allows for a complete upgrade of the Fueling Machine operating systems to an as-new condition within a scheduled maintenance window.

BWXT collaborated closely with OPG and several key vendors to solve numerous supply challenges to successfully provide components and assemblies, many of which had not been manufactured in over 30 years. This project positions the Darlington Fuel Handling system for critical and reliable reactor fueling beyond 2050.

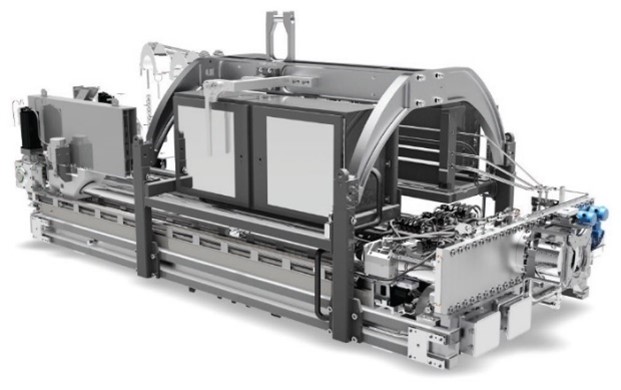

In 2017, BWXT and OPG partnered to reinsert Canada as a leading supplier in the Molybdenum-99 (Mo-99) market in support of medical diagnostics and imaging. The purpose of this project was to install a safe, reliable, efficient and cost-effective system to supply the medical isotope industry with irradiated Mo-99. This included the development of all major equipment and processes for the insertion into core, irradiation and harvesting of targets at OPG’s Darlington Nuclear Generating Station.

BWXT’s diverse capabilities provided the ability to execute the design, manufacture, assemble, test and install almost all scope items in the products life cycle.

The Target Delivery System is a nuclear piping system with innovative custom components that transfers targets in and out of the reactor in a completely automated manner. Targets are propelled through the system using pneumatics and hydraulics to an elevator system where they are lowered into the core of the reactor. The targets are raised and then propelled into a flask that is ready for shipment to BWXT’s nuclear medicine facility in Kanata

BWXT designed and supplied customized tooling to support Cobalt-60 retrieval at OPG’s Darlington Nuclear Generating Station.

The Cobalt 60 Flask Positioner Assembly is required to safely retrieve Cobalt elements from the adjuster ports of the reactivity mechanism deck. These strings are typically irradiated in the core for 2-3 years and then harvested during reactor outages. These modifications will be installed on all four reactor units at OPG’s Darlington Nuclear Generating Station.

BWXT developed the positioner assembly, which is used to carry the load off, position, and align the Flask and Pedestal with the desired adjuster port site such that the element string can be retrieved.

Collaborating closely with OPG, E.S. Fox, and Tetra Tech, we worked together to solve this problem, leveraging the broad skillset of our various teams, including engineering, manufacturing, quality assurance, procurement, and project management. This innovative product that will be instrumental in the ongoing harvest of life-saving medical isotopes.

In 2013, Bruce Power identified the need for a new generation of delivery systems to accelerate fuel channel inspections.

BWXT was intimately involved in all aspects of the evolution of BRIMS; from conceptual and detailed design, integration of OPEX from MiniSLAR and Universal Delivery Systems, through to the testing, and commissioning.

BRIMS is a remotely operated machine that delivers specialized inspection and maintenance tools into the reactor fuel channel. Not only does this advanced system reduce radiation doses to workers, but it also reduces outage times and increases safety in the workplace.

To this day, BWXT provides on-going upgrades, parts supply, maintenance and support of BRIMS.

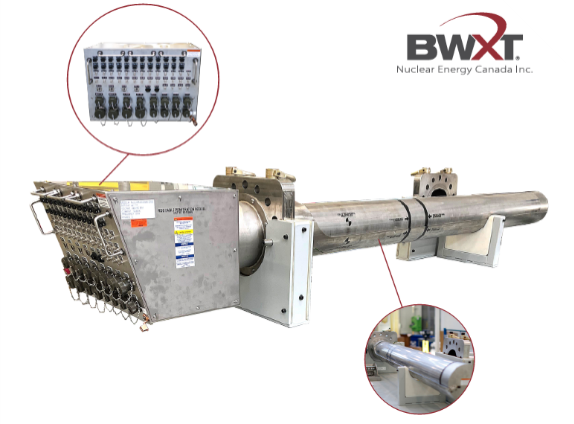

BWXT designed and supplied the Vault Penetration in support of OPG’s DNGS Rapid Deployment Machine (RDM). This critical component is temporarily installed in the containment wall of the reactor vault and allows for power, control, and signal cables to pass through while safely maintaining the reactor containment boundary.

The system includes the penetrations themselves as well as transportation carts, specialized tooling, a leak test fixture, and an electrical twin ‘test cart’. The leak test fixture allows for validation of the system prior to use as well as training for the operators, while the test cart allows for operation of the RDM in a non-production environment. The BWXT team worked through the various challenges including a complex procedure for assembling the cables to ensure they are leak tight.

BWXT supplied two of these systems in 2023.

© 2025 BWX Technologies. Inc. All Rights Reserved.

Privacy | Contact Us | Terms of Use

The products and services described herein are provided by subsidiaries of BWX Technologies, Inc.