OVERVIEW

With over 50 years of experience in research and design of nuclear equipment, BWXT has developed a comprehensive suite of capabilities related to thermal-hydraulic analysis, computational fluid dynamics analysis (CFD) and flow induced vibration (FIV) and wear analysis. Our tools include proprietary software developed by BWXT for specific applications, and the latest commercially available software for CFD analysis and heat exchanger design. Using these tools, our engineers can solve a wide range of thermal-hydraulic problems related to steam generators, heat exchangers, piping and other process systems.

APPLICATIONS

Typical application of BWXT’s capabilities in this area include:

- Thermal-hydraulic analysis of recirculating and once-through Steam Generators (SG) for design qualification and to assess the impact of changes in operating conditions (power uprate, changes to RCS operating temperatures, etc.) or due to aging (fouling, deposition, plugging)

- Thermal-hydraulic analysis of heat exchangers to assess the impact of changes in operating conditions or due to aging

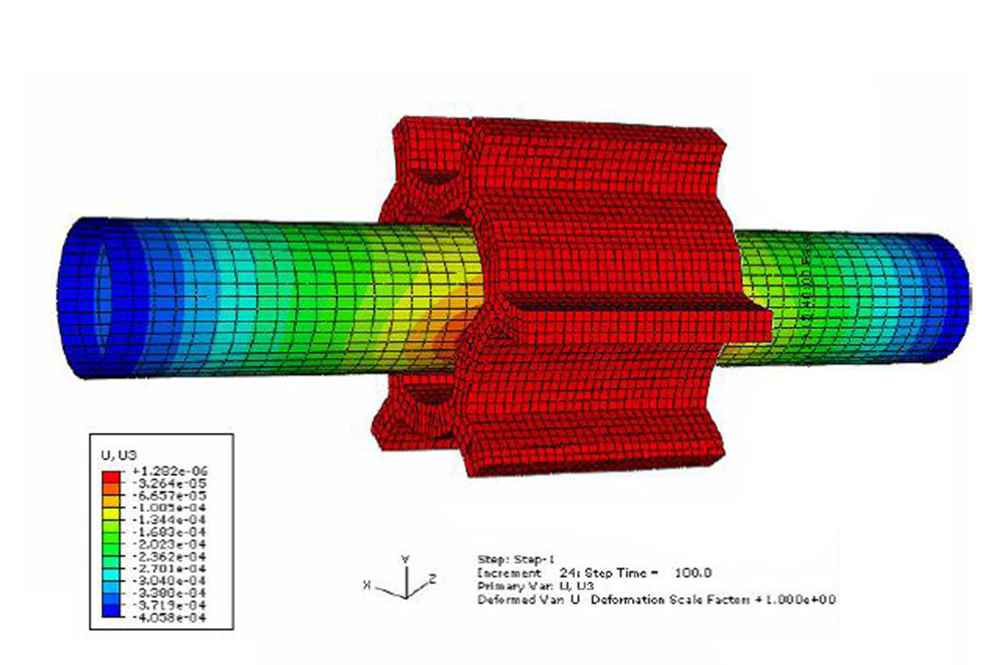

- CFD analysis of vessel features or systems to determine flow patterns, pressure drop or thermal stratification. These results are used for subsequent design analysis and to assess degradation (FAC), deposition, or thermal fatigue of the components.

- Flow induced vibration analysis of SG or heat exchanger tubes to determine susceptibility to vibration and tube wear. These analysis can address the effects of vessel modifications or aging (fouling or degradation of tube supports) and the effect of changes in operation conditions.

CAPABILITY AND TOOLS

BWXT’s thermal-hydraulic analysis toolbox includes proprietary software developed and validated by BWXT along with the latest commercially available CFD and HX software.

- ANSYS® CFX® Velocity Vector Plot of Bundle Entrance Region for OTSG

- Plot of Mesh Density in the Ring Header and Riser for Particle Tracking in OTSG Feedwater Train

- ANSYS® CFX® Velocity Vector and Contour Plot at 1000 GPM Flow Local to First Riser from Tee in OTSG Feedwater Train

Proprietary software includes one-dimensional and three-dimensional thermal-hydraulic codes for steam generator performance and circulation analysis and linear and non-linear analysis codes for FIV and tube wear analyses.

Commercial software includes ANSYS® CFX® for general CFD analysis, HTRI XistTM for heat exchanger thermal analyses and sizing, UniSim for feedwater heater analysis and sizing, and RELAP5TM for transient thermal-hydraulic analysis.

The proprietary and commercial software used by BWXT for nuclear safety-related contracts is fully qualified in accordance with our QA Program, which is compliant with ASME NQA-1.

ANSYS® is a registered trademark of ANSYS, Inc.

CFX® is a registered trademark of Sony Corporation.

HTRI XistTM is a registered trademark of HTRI.

RELAP5TM is a registered trademark of Innovative Systems Software.