Modifications to nuclear plant components are often required as components age. These modifications may be required to improve access for inspection or maintenance, to repair in-service degradation and damage, or to address other plant-related needs. BWXT's experience designing and providing field services to nuclear pressure vessel equipment enables our engineers to design and qualify practical vessel modifications that are optimized for field installation.

APPLICATIONS

BWXT’s experience and capabilities include qualification of a large range of field modifications,including:

- Modification of openings

- Field-installed inspection ports and handholes (often without the need for welding to the pressure boundary), including unreinforced or partially reinforced designs

- Installation of Helicoils™ to repair damaged threads

- Installation of Hydra-Nuts™

- Operation with damaged or missing studs on openings

- Changes of gasket materials

CAPABILITY AND TOOLS

BWXT has developed extensive knowledge in bolt design and analysis, gasket selection, gasket seating design, gasket analysis and seal-weld analysis through years of experience with gasketed and seal-welded openings subject to pressures in excess of 3000 psi.

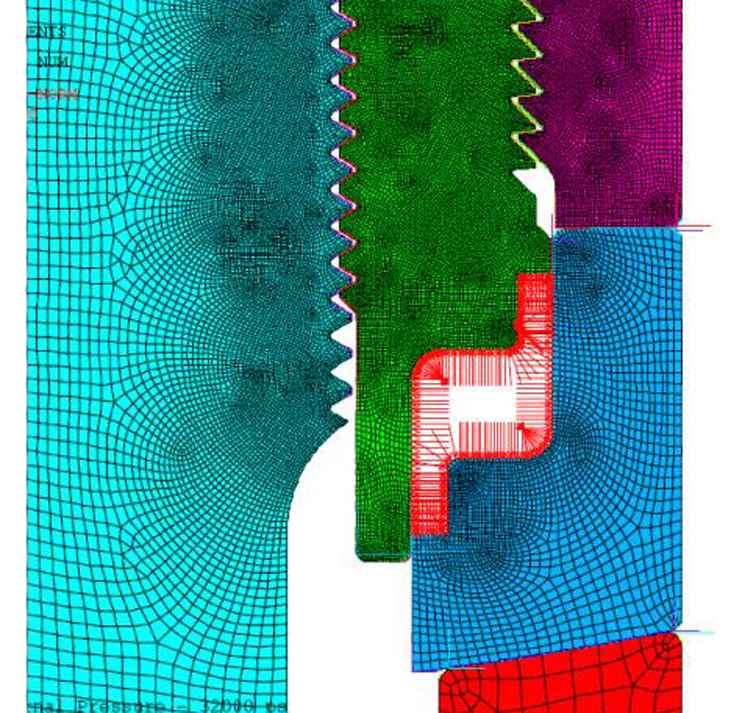

BWXT performs gasket analyses using a variety of methods, both rule-based (ASME and PVRC methods) and numerical-based, using commercial Finite Element (FE) codes (ANSYS®, ABAQUSTM).

Capabilities include:

- Selection of gaskets based on joint behaviour, gasket stiffness and leakage requirements

- ASME Code design of gasketed joints/bolts, including thermal transient and fatigue analysis

- Selection of bolt assembly preloads for good gasket seating and no-leakage during operation

- Gasket and bolt design using the PVRC method, including interpretation of Room Temperature Tightness (ROTT), gasket test data and their application to bolt design

- Finite element modeling of non-linear gasket behavior including elastic-plastic modeling for the prevention of gasket leakage

- Prediction of joint rotation and optimization of joint geometry

- Fatigue analysis of seal welds

ANSYS® is a registered trademark of ANSYS, Inc.

ABAQUSTM is a registered trademark of Dassault Systems.

HelicoilsTM is a registered trademark of Emert Technologies.

Hydra-NutsTM is a registered trademark of Curtis-Wright Corporation.