BWXT has extensive experience in the inelastic design of pressure vessel components. This is comprised of Limit Analysis design according to ASME Code Section III, NB- 3228.1/Section VIII, Div. 2, 5.2.3 Plastic Analysis according to Section III, NB-3228.3 / Section VIII, Div. 2, 5.2.4 and other non-code design considerations. Due to its ability to isolate primary stresses, elastic-plastic analysis uses the available load carrying capacity of a structure in the best way possible without compromising the overall safety of the structure against failure by excessive deformation.

APPLICATIONS:

For many components, the use of inelastic analysis results in a much more efficient design than what can be achieved with elastic methods or “design by rule”. This can mean less weight, less weld volume and even lower thermal stresses and better fatigue life, depending on the specific geometry and loads on a structure. These techniques can also be used in some cases to requalify a pressure vessel component that has undergone significant erosion, repair or over-pressurization.

Examples of elastic-plastic analysis performed at BWXT include:

- Design and justification of partially reinforced and unreinforced access openings

- Design of elliptical steam drum heads

- Design of vessel/nozzle intersections

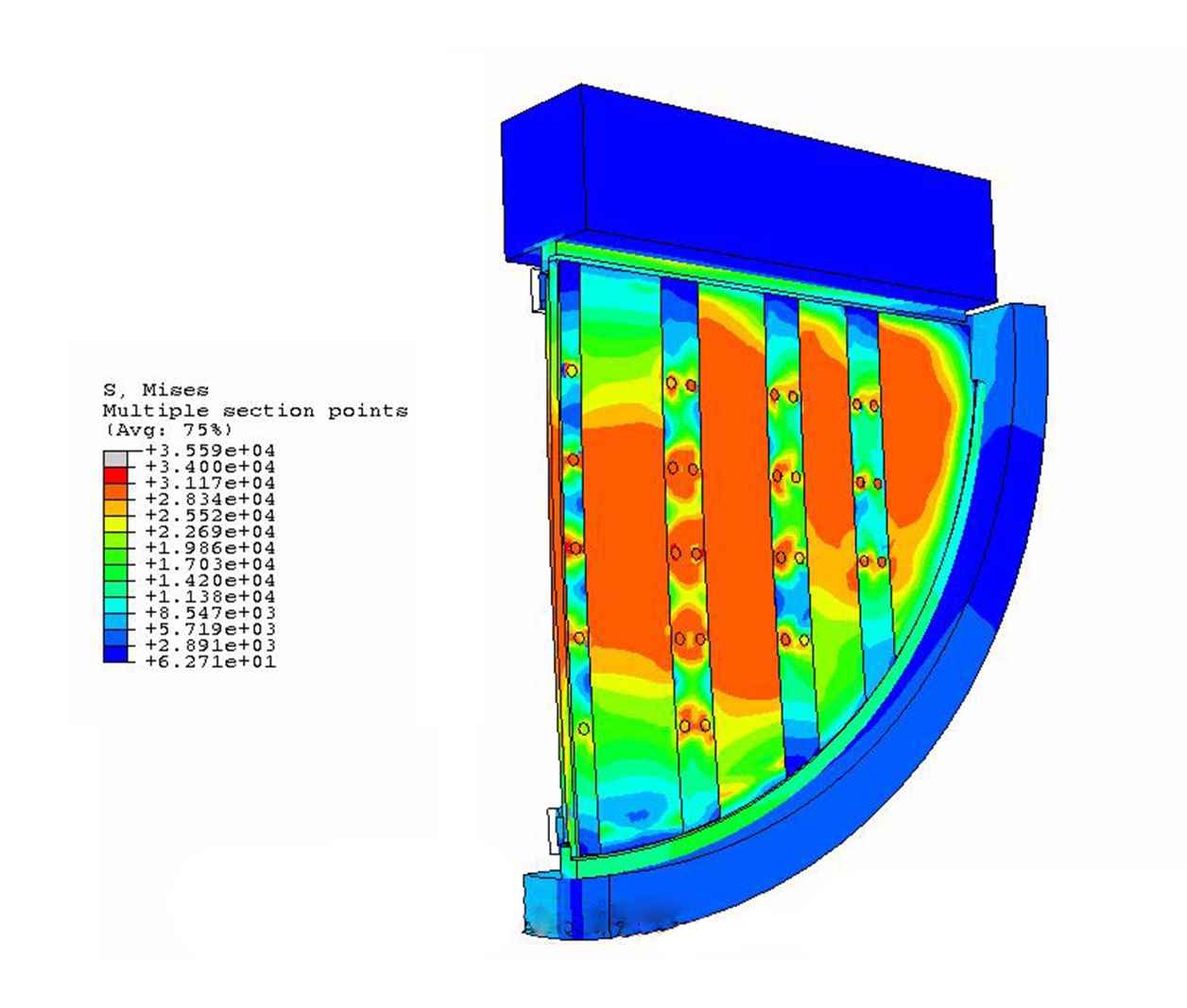

- Evaluation of welded and floating divider plates under design and design basis loads

- Elastic-plastic cyclic analysis of divider plates

- Elastic-plastic design of tubesheets and other perforated structures

- Modeling of a hydraulic tube expansion process

- Elastic-plastic gasket modeling

CAPABILITY AND TOOLS:

BWXT has a variety of methods available to perform inelastic analysis with proven commercial Finite Element (FE) codes (ANSYS, ABAQUS).

Capabilities include:

- Primary stress or limit analysis through elastic iterations

- Elastic-perfectly plastic limit or primary stress analysis

- Plastic analysis, including hardening and non-linear geometric effects

- Analysis of anisotropic and perforated structures

- Explicit FE analysis for highly non-linear problems

- Inelastic transient and fatigue analysis

The analysis method can be selected based on the nature of the problem to be analyzed and the preference of the client.

ANSYS® is a registered trademark of ANSYS, Inc.