OVERVIEW

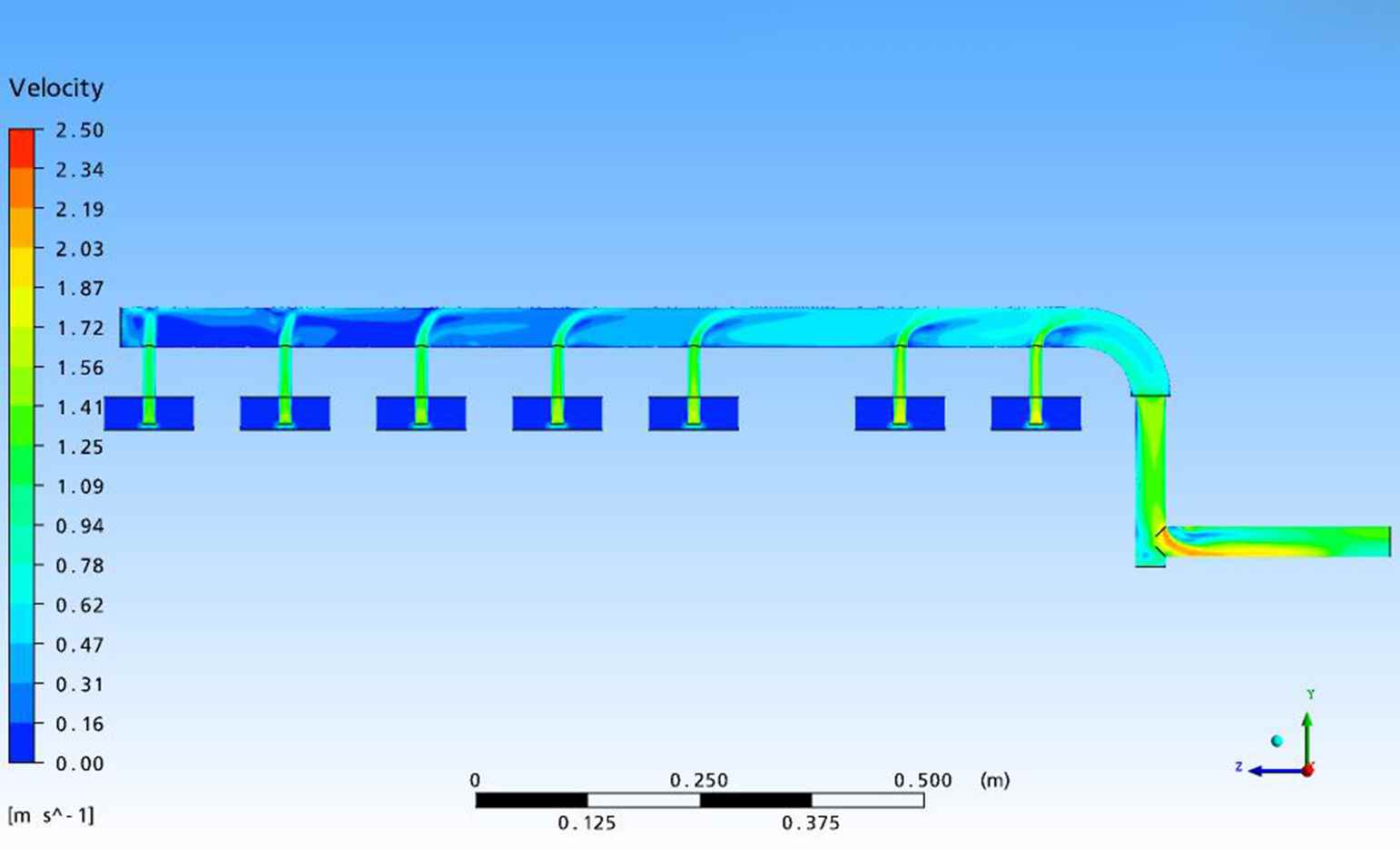

Computational Fluid Dynamics (CFD) is used to model a wide range of single and two-phase flow conditions. Applications can include entire vessels or piping systems, or specific design features of new or modified components. In other situations, CFD has been applied to determine the cause or consequence of degradation of components.

These evaluations provide a quick and cost-effective means of assessing the flow conditions, temperature profiles and pressure drops within a variety of plant systems. The results are used by BWXT engineers to demonstrate the acceptability of the system, or to improve safety and reliability by gaining an appreciation of the potential for future failures due to degradation or thermal fatigue.

APPLICATIONS

BWXT has used CFD analysis to solve complex engineering challenges related to:

- Predicting the two-phase flow through the secondary side of a recirculating Steam Generator (SG) to assess the impact of fouled or degraded tube supports

- Thermal stratification in feedwater distribution systems during a startup transient

- Thermal stratification in PWR pressurizer surge lines

- Leakage flow through a degraded feedwater thermal sleeve

- Velocity and pressure distribution in and downstream multi-venturi style flow restrictors located in the steam outlet nozzle

- Particulate entrapment in regions of quiescent flow on the secondary side of the SG

- Natural convection heat transfer during post weld heat treatment of pressure vessel closing seams

The range of potential applications for CFD analysis is almost limitless, and continues to expand due to increases in computing power and software improvements.

CAPABILITY AND TOOLS

BWXT applies ANSYS® CFX®1 software to perform a wide range of computational fluids dynamics analysis. This software is capable of accurately modeling complex geometric configurations, and providing detailed distributions of pressure, temperature, velocity, density, turbulence intensity and other parameters.

ANSYS® 14 combines direct CAD input, automatic meshing and a unique Coupled Algebraic Multigrid algorithm where pressure and momentum conservation equations are solved simultaneously, reducing the CPU time needed to run CFD simulations. Features include conjugate heat transfer, fluid-structure interaction and various level of turbulent modeling up to large eddy simulations. CFX® is constantly validated against industrial benchmarks for speed, accuracy and versatility.

ANSYS® is a registered trademark of ANSYS, Inc.

1 CFX® is a registered trademark of Sony Corporation.