BWX Technologies, Inc. (BWXT) maintains extensive facilities for analyzing and testing radioactive materials at the Lynchburg Technology Center, located in Virginia.

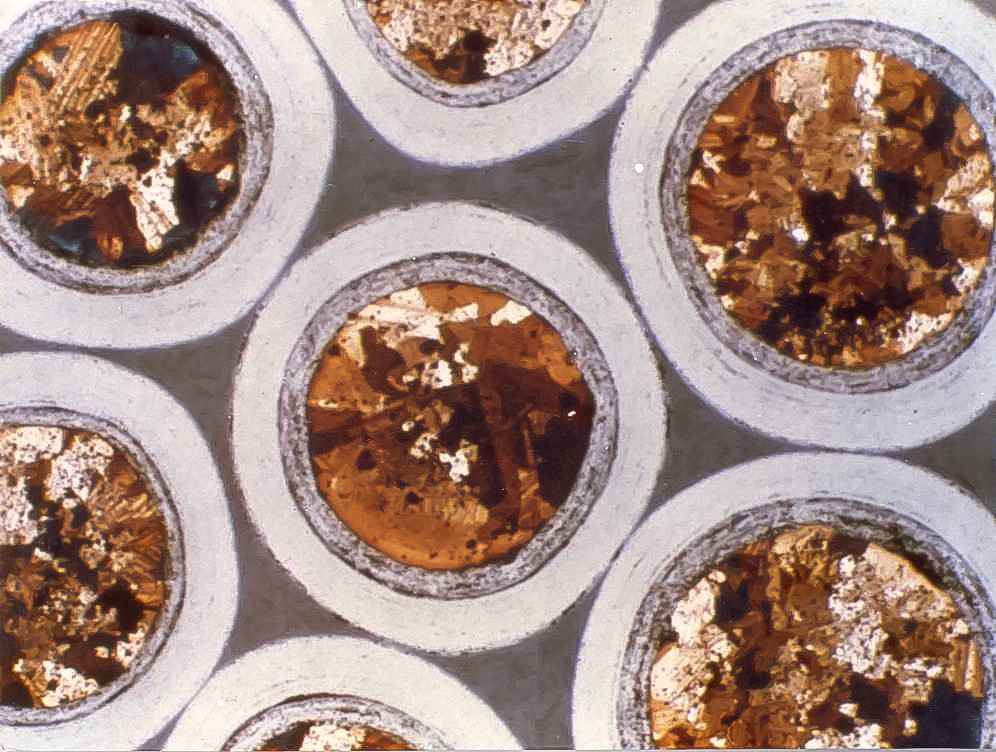

The Strategic Materials Laboratory (SML) is a radiologically-controlled area where nuclear and non-nuclear materials are processed and evaluated. This laboratory is used to develop and test nuclear fuel and related components as part of the Nuclear Materials & Inspections Systems at the facility.

BACKGROUND

For more than 40 years, BWXT’s Lynchburg Technology Center has supported the company’s interest in the nuclear industry.

The SML was built in the late 1980s for processing, developing and testing advanced nuclear fuels and their components under the U.S. Air Force Space Nuclear Thermal Propulsion Program.

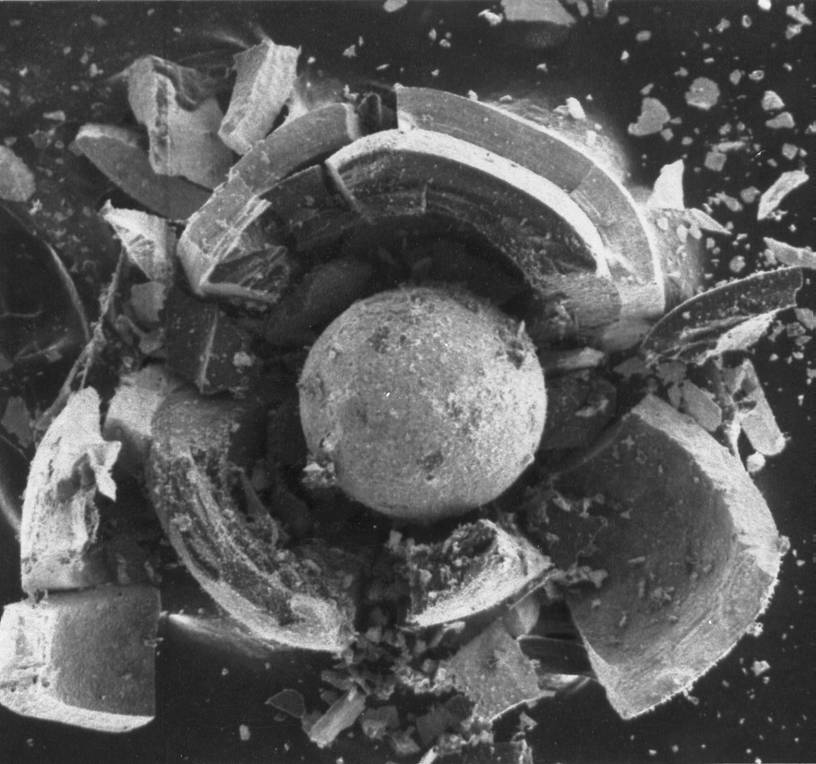

The laboratory supported the development and testing of coated particle fuel for advanced particle-bed reactors. Other notable projects have included high-temperature fuel development for advanced reactors, solar bimodal propulsion and work on Russian high-temperature fuel.

CAPABILITIES

Nuclear and non-nuclear materials can be processed, tested and characterized in the SML by our staff of metallurgists, ceramists and technicians. We support both internal and external customers.

Laboratory test facilities include:

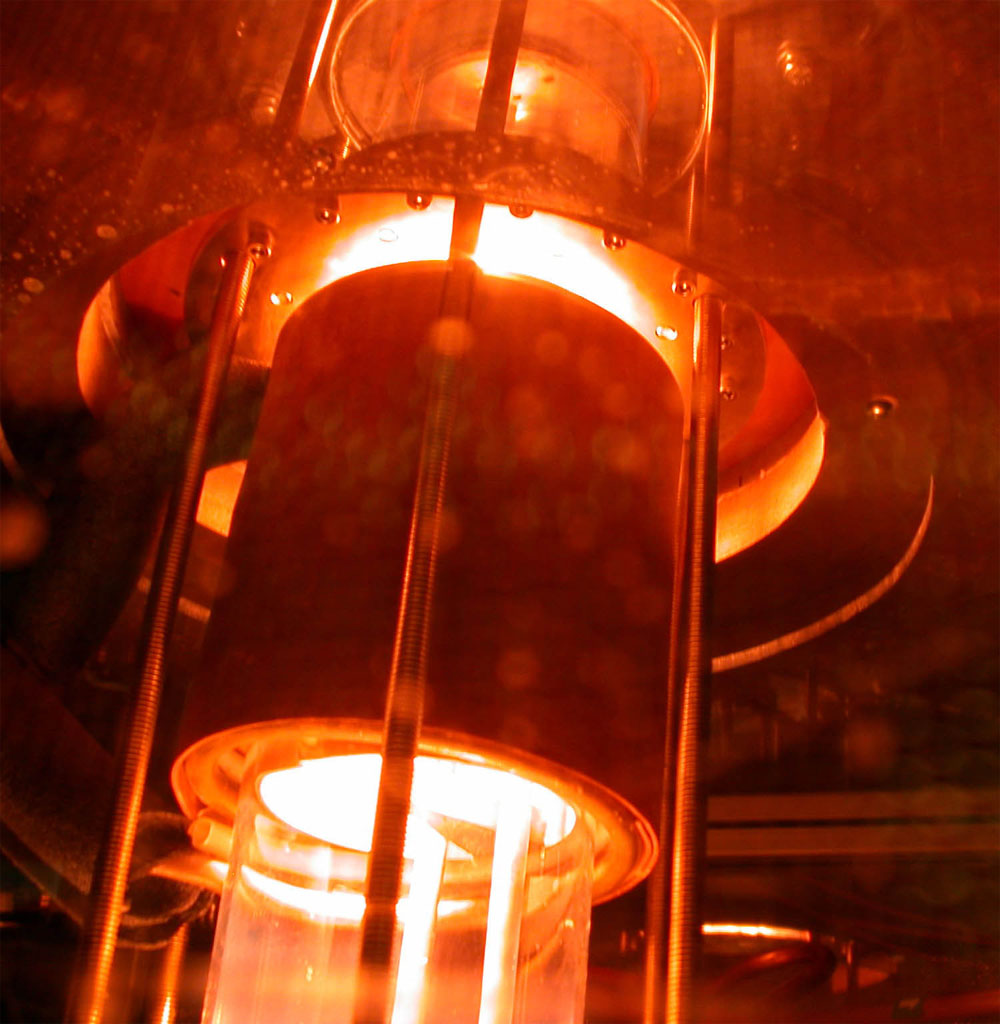

- High-temperature (>3000°C) exposure in inert gas of 100% hydrogen

- Deformation (plasticity)

- Static and dynamic compression

- Bed thermal expansion

- Thermal stability / interaction / compatibility • Cyclic temperature

- Melt-point determinations

Processing facilities include:

- High-temperature induction furnaces

- High-temperature graphite furnace

- Hot isostatic pressing

- Cold isostatic pressing

- Chemical vapor desposition / infiltration

- Supercritical fluid infiltration

- Hot machining

Other section facilities include:

- Scanning electron microscopy with x-ray microanalysis (EDS/WDS)

- Hot cell facilities (rated to 300,000 curies)

- Electron microprobe

- Mechanical testing