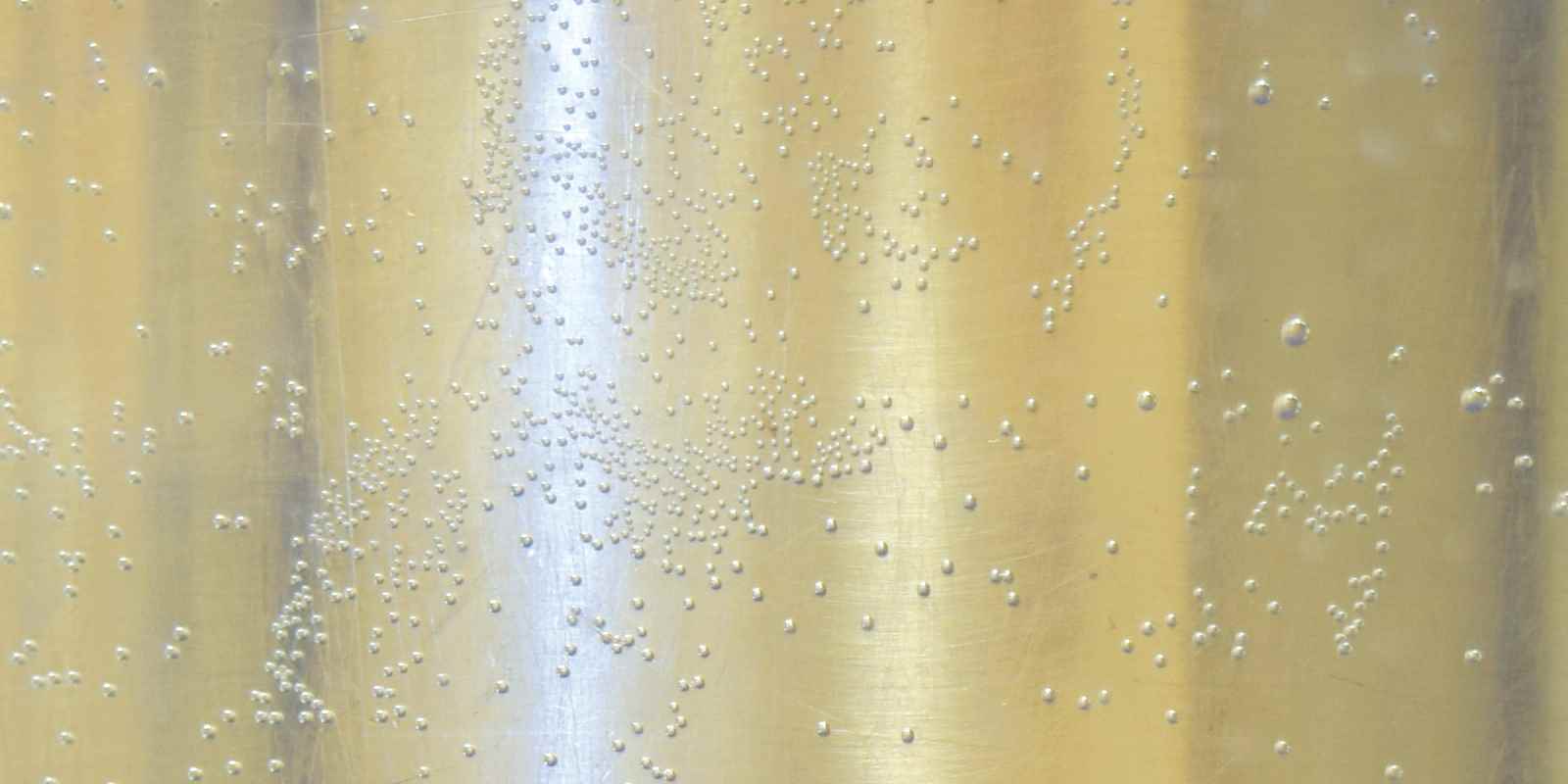

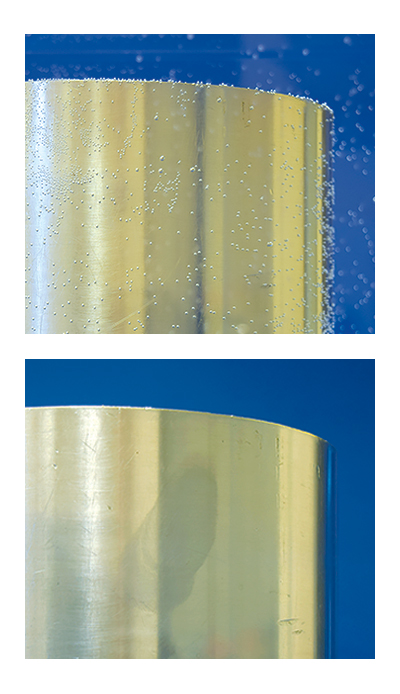

Bubble formation without the Bubblevac system (top) Same tank refilled with the Bubblevac system (bottom)

The Bubblevac™ Automated Degasification System is a pioneering product for the ultrasonic testing community. By eliminating dissolved gasses in water couplant, scan quality increases, incidents of re‑scans due to bubble formation decrease, and total downtime due to water replacement can drop by more than 98%. The Bubblevac system is also well suited for squirter systems - a single Bubblevac system can handle flow rates up to 10 gpm.

A 500-gallon ultrasonic testing (UT) tank can be filled in less than an hour using the Bubblevac system, and the tank is ready to use as soon as it is filled. Without a Bubblevac system, a typical UT tank can sit idle for three days as it waits for bubbles to disperse.

Built with reliability in mind, the Bubblevac system is fully enclosed, so its internal components are protected. The system incorporates an industrial-grade touch screen user interface and PLC. It also uses an automatic purge cycle to reduce required maintenance and prolong the life of the unit.

Specifications

Inlet water conditions:

- Temperature: 41-86°F

- Max Pressure: 80 psig

- Flow Rate: 10 gpm

- Filtered to 5um

Water Connections:

- Inlet: 1” FNPT

- Outlet: 1” FNPT

- Drain: 1/2" FNPT

Compressed Air Connection:

- 3/8” Push-To-Connect

- 10 SCFM @ 80 psi filtered to 0.2um

Power Requirements:

- 120V AC, 60 Hz, 15A receptacle

Dimensions (approx):

- 72”(h) x 32” (w) x 20”(d)

This system can be customized to meet specific needs.

Contact us for availability.

For more information on the Bubblevac System, please email NDE@bwxt.com.