BWX Technologies, Inc. (BWXT) has the experience, expertise, and operational flexibility to design and build steam generators to the demanding specifications of each of our individual customers.

BWX Technologies, Inc. (BWXT) has the experience, expertise, and operational flexibility to design and build steam generators to the demanding specifications of each of our individual customers.

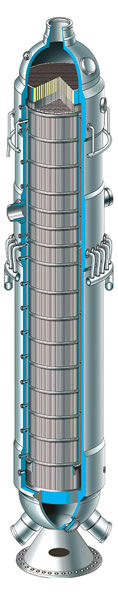

The OTSG has a vertical-shell counterflow straight-tube heat exchanger design, which directly generates superheated steam as the feedwater flows through the steam generator in a single pass.

BWXT is the exclusive designer and manufacturer of OTSGs for the nuclear industry.

- Full-pitch pattern occupied by tubes or tie-rods

- No tube-free lane (eliminates moisture carry-up into superheated regions and localized high velocities)

We consistently meet or exceed OTSG design objectives:

- Create “form, fit, and function” design to simplify licensing

- Retain all terminal points

- Overall performance consistent with existing steam generators

- Structural compatibility with Nuclear Steam Supply System

- Design for reliability

- Minimize tube residual stress

- Avoid flow-induced vibration

- Assure high-steam superheat under all operating conditions

- Prevent loose parts

- Facilitate inspection and maintenance

REPLACEMENT STEAM GENERATORS (RSG):

Of the 69 operating pressurized water reactor nuclear power plants in the U.S., 56 had 163 individual steam generators replaced or awarded by 2005. Additional RSG replacements are anticipated as the remaining installations age.

The previously unanticipated aging issues experienced by nuclear steam generators usually involve complex interactions between the construction materials, water chemistry operation and contaminant ingress, tube support arrangements, fabrication techniques and local thermal-hydraulic conditions.

BWXT’s advanced series RSGs are designed with cutting-edge technology available to overcome steam generator issues while still meeting or exceeding all steam generator functional requirements.

Our RSGs are designed to support the extension of power plants’ operating lives. In many cases, plants with replacement units have received extended licenses to operate 20 years beyond the original plant life span, and they may eventually operate even further. To achieve these objectives, while combating the causes of component degradation, we place emphasis on upgrading component materials, introducing advanced design features and manufacturing methods, and incorporating the latest technical developments.

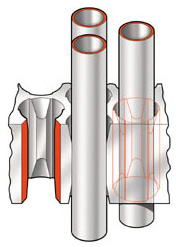

Hour-glassed broached plate configuration:

- Reduces pressure drop

- Provides flat surface contacts between tube support plates and tubes

- Facilitates tubing

- Offers more accessibility for water-lance, chemical, or water-slap cleaning

Tube bundle arrangement

- Full pitch pattern occupied by tubes or tie-rods

- No tube-free lane (eliminates moisture carry-up into superheat regions and localized high velocities)