Additive Manufacturing

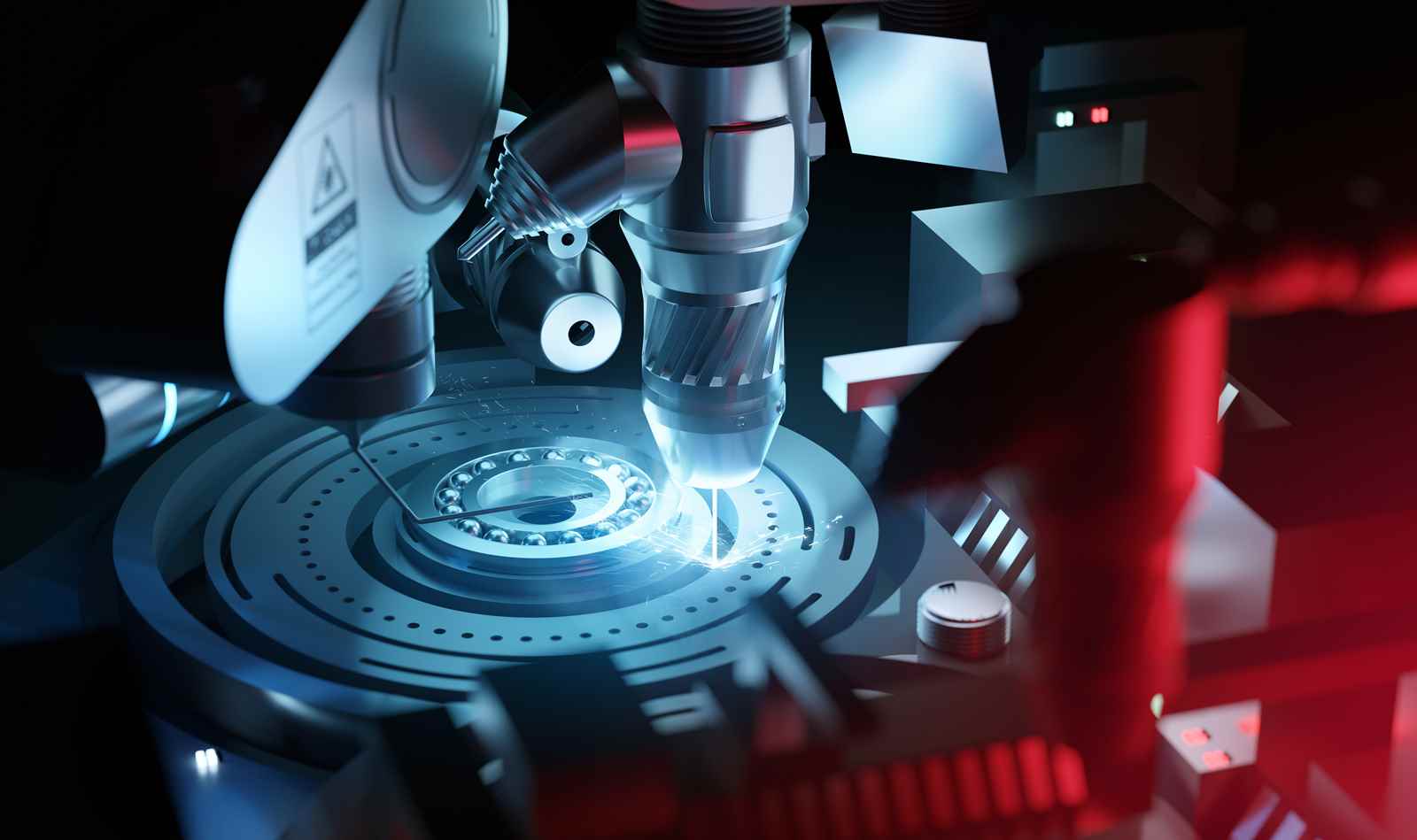

The development of advanced nuclear reactors is continuing rapidly, but there remain issues surrounding the use of some of the specialty materials that are important to these reactors. Working with Oak Ridge National Laboratory, engineers and designers at BWXT Advanced Technologies LLC (BWXT AT) have developed new additive manufacturing technologies to design and manufacture reactor components made from high-temperature alloys and refractory metals.

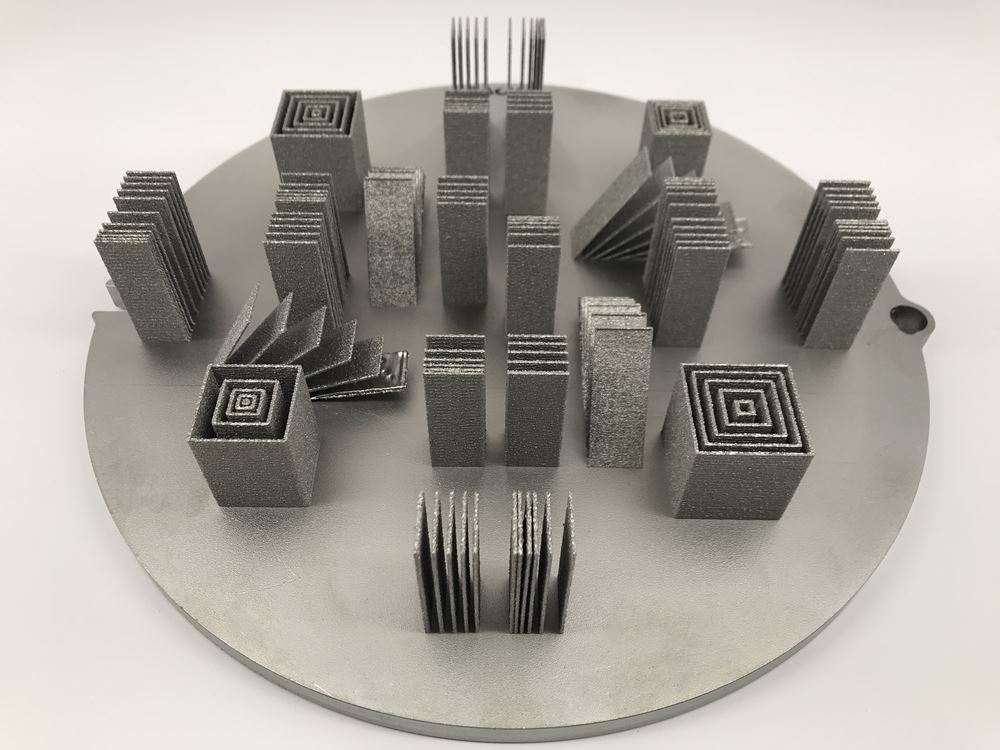

Specifically, BWXT AT has demonstrated the ability to additively manufacture nickel-based superalloys and refractory-metal-based alloys for nuclear components. BWXT AT also accomplished component-level qualification, leading to a more efficient certification of nuclear materials configured in complex geometries. BWXT AT validated this technology during the successful execution of an advanced nuclear technology development cost-share program, which was awarded by the U.S. Department of Energy in 2018.

Additive manufacturing technologies will be transformational for the nuclear industry - they will enable the creation of shapes that simply cannot be made via conventional manufacturing techniques. Additionally, verifying the ability to additively manufacture high-temperature superalloys and refractory metals will enable designs with improved thermal energy management, increased safety margins, and accident-tolerant characteristics.

With refractory metal alloy-based core components, it is conceivable that an advanced reactor can reach core exit temperatures of 2,700°F and increase overall plant efficiencies by approximately 50%.

These material developments could have an immediate impact on the world’s commercial reactor fleet while also bringing the nuclear industry closer to achieving an accident-tolerant fuel design.

BWXT AT will use its unique design expertise and advanced manufacturing capabilities to reduce the costs of advanced nuclear energy systems. BWXT AT’s designs and manufacturing methods will enhance reactors’ power output and longevity while maintaining affordable manufacturing costs.