CANDU Steam Generator Tube Inspection and Repair

Power Your Career

Home » Sectors » Nuclear Energy » Field & Engineering Services » Steam Generator Services » CANDU PHWR Steam Generator Tube PRIMA® Inspection and Repair

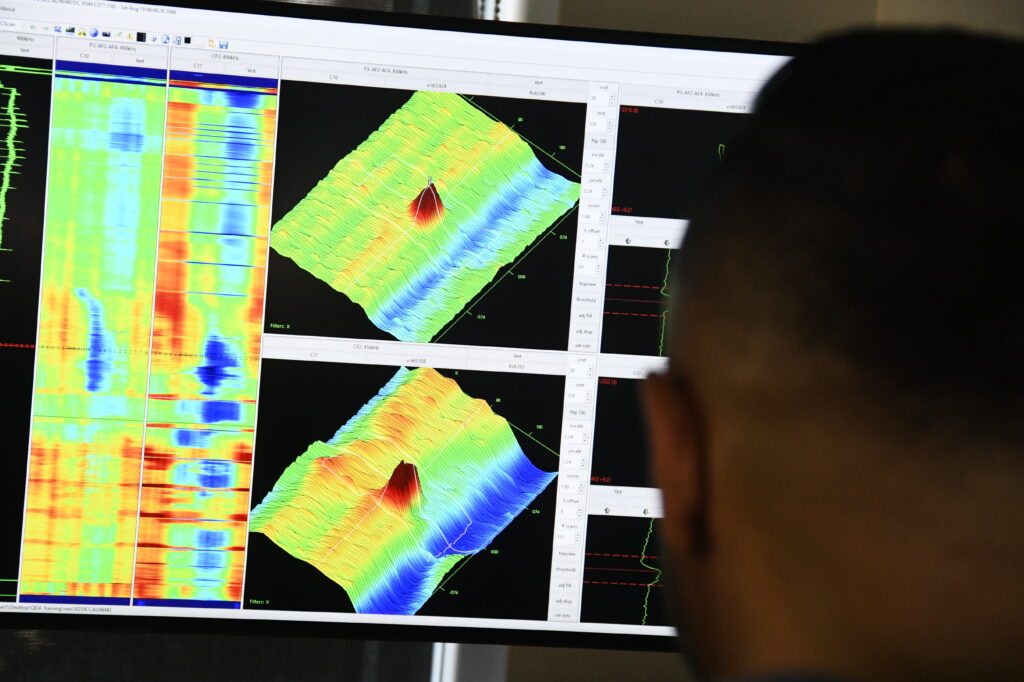

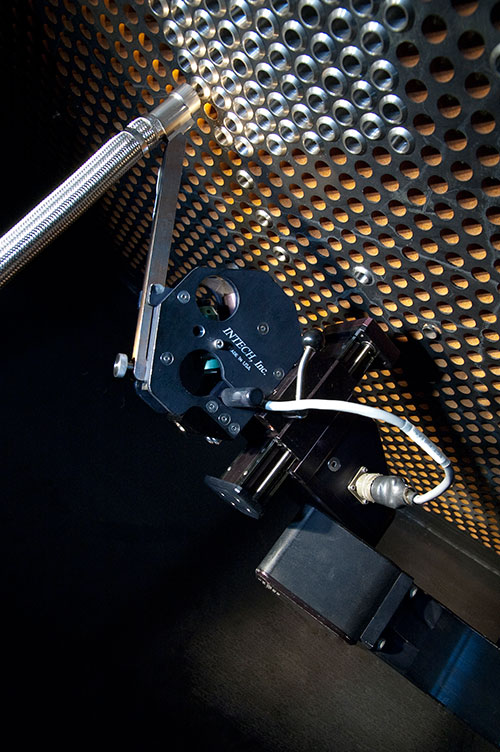

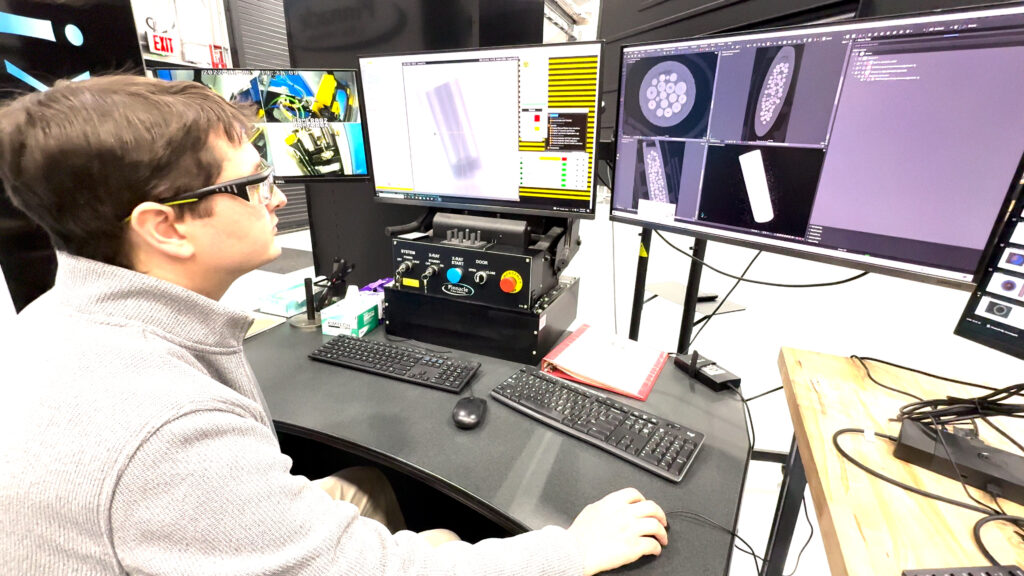

Our commitment to efficiency and safety in nuclear operations is shown through our development of the PRIMA™ SG robotic manipulator, which offers improved speed, accuracy and durability during steam generator inspection and maintenance.

PRIMA™ SG significantly reduces inspection time and minimizes operator radiation exposure. Designed and built in-house, this system is engineered for rapid tool changes and handles all automated tube plugging and removal tasks.

Key benefits:

- Fast and efficient: Proven 10-minute field installation and negligible tube-to-tube speed (4 ft/second)

- Enhanced safety: No personnel entry into the vessel is required, minimizing radiation exposure (ALARA principle)

- Precision and reliability: Single-point calibration, failsafe calibration retention and zero inspection exclusion zones

- Versatile and robust: Lightweight, three-piece design for easy transport and assembly, 100 pounds payload capacity and compatibility with industry-standard data acquisition units and tooling

- Clean and simple: No pneumatic air requirements, no striding or tube walking and no metal-to-metal gripping of tubes

PRIMA™ SG has been successfully deployed in Canada and internationally.