Energy fuels the U.S. military mission, but diesel generators require a long logistics tail that costs time and can risk soldiers’ safety. The U.S. Army needed a resilient, swiftly deployable energy source for wherever needed, including remote bases, harsh environments and disaster response.

Enter Project Pele: a transportable nuclear power system designed by BWXT and sponsored by the U.S. Department of War’s Strategic Capabilities Office. The Pele microreactor:

Once deployed, the Pele microreactor will generate resilient baseload power for contested environments and other mission-critical military needs.

Tough enough to get to the point of need:

Designed to meet rigorous shock and vibration requirements, the Pele system provides flexibility for transport by truck, train and airplane.

Strong and Compact:

The reactor and power systems fit inside four standard 20-foot shipping containers and deliver 1.5 MW of reliable, pollution-free electricity.

Reduces long logistics tail:

The Pele system cuts down on the time, effort and risk of securing and transporting fuel for diesel-powered generators, offsetting up to

1.5 million gallons of diesel and eliminating hundreds of fuel truck deliveries each year.

Expands mission-critical supply chain:

The Pele system broadens the Gen-IV reactor supply chain while maintaining the highest safety and quality standards.

With manufacturing already well underway, Pele will be the first fully tested advanced microreactor power generation system to power Army equipment and meet the Sept. 30, 2028, deadline for Executive Order (EO) 14299, “Deploying Advanced Nuclear Reactor Technologies for National Security.”

The mission for BWXT: design, build and test a completely integrated and functioning reactor prototype – not just a reactor physics test or minimally viable product for low-power testing. Once complete, the Pele reactor will deliver baseload power for the Department of War’s most mission-critical efforts and operations – but it doesn’t stop there.

The benefits of Pele also extend to the nuclear industry at-large:

The Pele prototype is designed and manufactured at BWXT’s Innovation Campus in Lynchburg, Virginia, a state-of-the-art facility that brings together scientists, engineers and makers who execute new nuclear and first-of-a-kind projects to completion.

BWXT’s expertise and experience are foundational to Project Pele’s success:

Pele is a revolutionary Generation IV high-temperature gas-cooled reactor (HTGR), rooted in proven technologies. Achieving its compact size and high-power output demanded rapid, cutting-edge innovation across multiple areas, including:

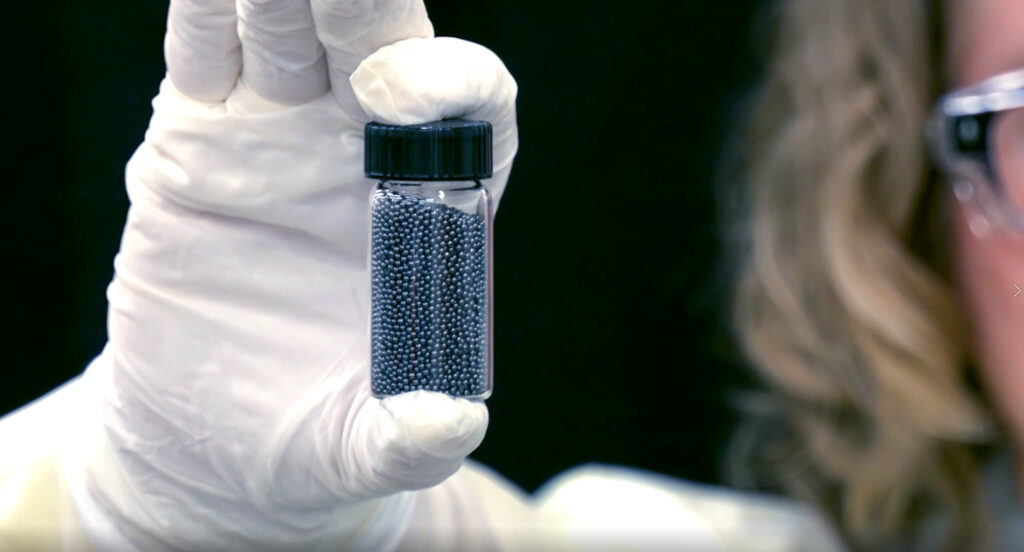

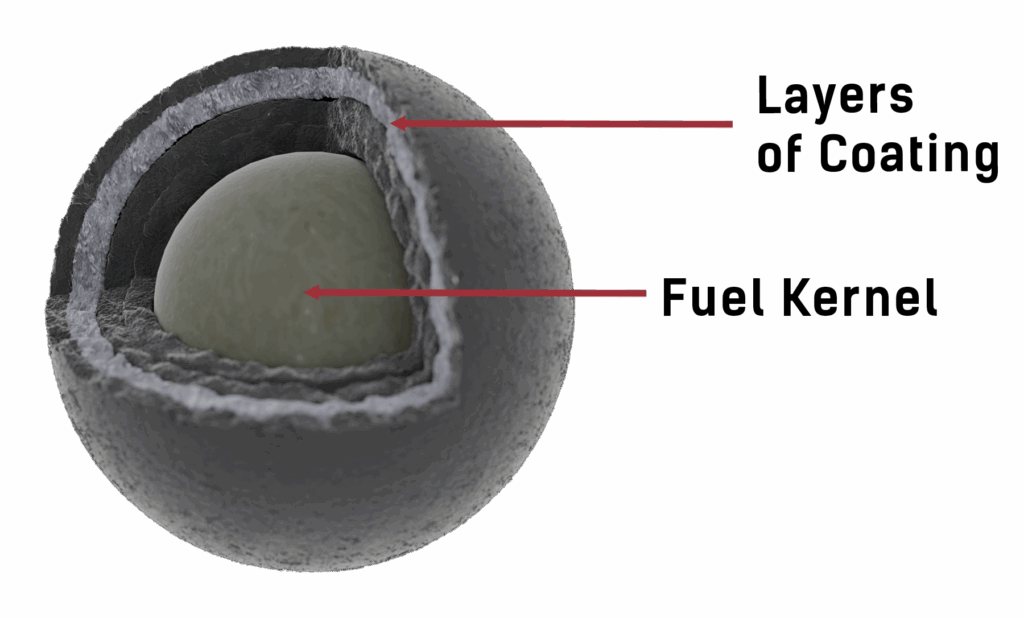

The Pele microreactor is powered by TRi-structural ISOtropic (TRISO) fuel, known for its advanced safety and output efficiency. Each poppyseed-sized uranium kernel is encased in a multi-layered, high-density ceramic shell, capable of withstanding extreme temperatures and corrosion, providing robust safety and reliability.

In just three years, BWXT advanced Project Pele from contract award to reactor fabrication and initial fuel delivery. As the prime integrator, BWXT is demonstrating unparalleled speed in design, development and manufacturing of microreactors and TRISO fuel.

Awarded contract by Strategic Capabilities Office to build and deliver Pele prototype.

Department of Energy authorized BWXT to begin ordering long-lead items; TRISO fuel manufacturing began.

System design

review completed.

Core assembly

production began.

TRISO fuel production completed for initial core load.

The PELE reactor will ship from BWXT’s Lynchburg facilities to Idaho National Laboratory. Once loaded with BWXT-produced TRISO fuel, the system will face rigorous demonstration tests to confirm its operational performance in simulated real-world operational conditions.

BWXT serves as the lead contractor for Project Pele and collaborates with best-in-class organizations for the complete powerplant:

Design and build of the thermal and power conversion modules and electrical delivery systems.

Design and build of the Pele control module, plant instrument and control systems, and semi-autonomous controls.

Module transportation and logistics.